Bronze is one of the earliest metals known to man. It is defined as an allow of copper. Art foundries commonly use modern bronze consisting of 95% copper, 4% manganese, and 1% zinc. However, it may also include small amounts of manganese, aluminum, and nickel. Because bronze contains a large amount of copper, it oxidizes over time when exposed to air, but only on its outer layer. This oxidation consists of copper oxide which eventually becomes copper carbonate. The oxide layer protects the interior metal from further corrosion. However, if chlorides are present (as from sea water), copper chlorides form which can cause “bronze disease”, a condition in which corrosion works through the metal destroying it.

Frostad Atelier Foundry can restore oxidized bronze back to its original condition. With large, monumental sculptures that are permanently installed, we restore the sculpture on site. The bronze is first heated with a torch in order to “open pores” and weaken the copper oxide. This is followed by hand scrubbing to remove the oxidation. The sculpture then undergoes repatinization. Finally, a sealer is applied to the new patina finish to protect the surface of the sculpture and lengthen the time before oxidation again occurs.

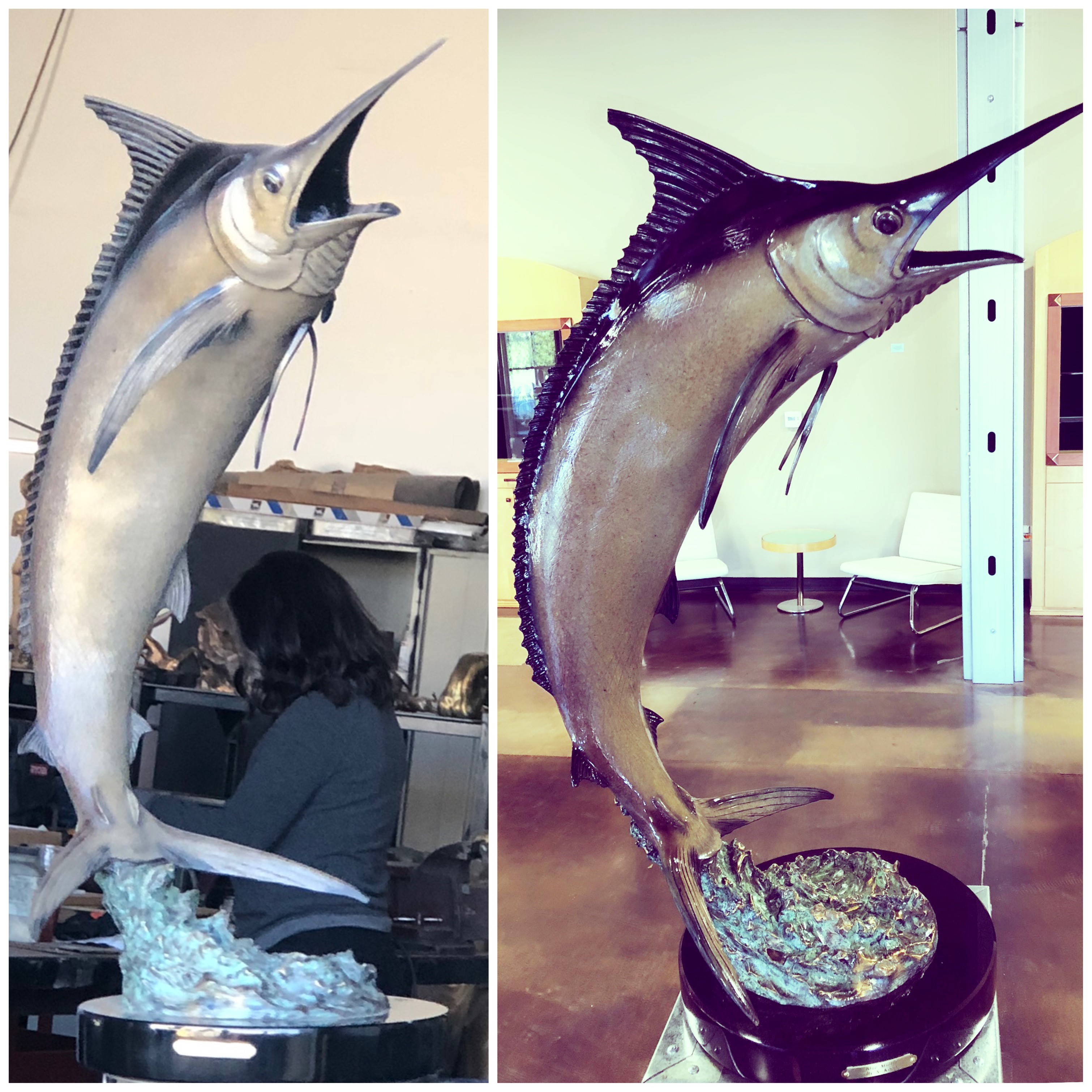

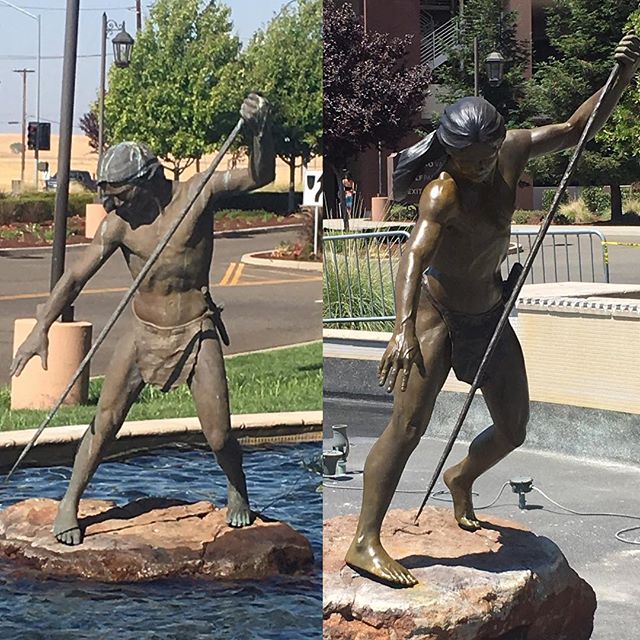

The examples below demonstrate the benefits of bronze restoration.

“Marlin”

“Marlin” “Linden Park”

“Linden Park” “Thunder Valley Casino”

“Thunder Valley Casino” “Sailors Union of the Pacific, SF”

“Sailors Union of the Pacific, SF”